RELEASE INFORMATION

Release date 30 DECEMBER 2021

Sold DIRECT VIA FPM AND VIA YOYOEXPERT, YOYOSAM And SPINGEAR

Retail 479.99 USD

OUTER RING BIMETAL DESIGN, RAW TITANIUM BODY WITH STAINLESS STEEL RINGS

55 MADE

Diameter 57mm, Width 44mm, Gap 4.4mm

Weight 64G WITH ONE DROP ENERGY DOME SIDE EFFECTS (INCLUDED)

YOYORECREATION NSK PLATINUM DOUBLE STRAIGHT C bearing

19MM TYPE 40 LANDING PADS RESPONSE

ANOTHER WORLD’S FIRST

The Doombot had many breakthroughs. It was the first titanium-brass bimetal yo-yo ever made. It has also remained the largest titanium bimetal yo-yo to date, with a diameter of 58 mm. Machining a titanium yo-yo of this size is complicated.

The Doombot had nearly discouraged me from making another bimetal titanium yo-yo, but the opportunity to make the world’s first titanium bimetal SE yo-yo made me want to challenge my limits.

I am proud to present to you, Droid.

OUTER RING TITANIUM BIMETAL DESIGN

RSO has been primarily making organic old school designs so far. A yo-yo made for competitive play was the number one request from the fans.

Given that Droid is to be a SE yo-yo, it is critical to have an outer ring design instead of an inner ring one - let me explain.

Due to the Doombot’s inner ring design, the diameter of its titanium body has to span the entire 58 mm. Such a large diameter increases the risk of warping of the yo-yo body during the machining process.

The titanium yo-yo body of Droid (without the outer rings) measures at a smaller and hence safer 54 mm, allowing the yo-yo to be machined more consistently. The outer rings make up the rest of the 57 mm diameter for Droid.

Droid ties with the MagicYoYo Rex, another yo-yo with an outer ring design, as the 2nd largest titanium bimetal yo-yo to date. Most of the titanium bimetal yo-yos that have been released are in the 56mm to 56.5 mm diameter rage.

Stainless steel was the only material I felt was suitable for the outer rings. An outer ring design necessitated a material that was durable enough as the rings would be in constant contact with the player’s hands. Brass was not an option as it is prone to discoloration, particularly with repeated hand contact.

POWER, SQUARED

Droid was mainly inspired by two yo-yos, the One Drop CiTizen and Turning Point Diaspora. The most apt way to describe it would be a bimetal CiTizen with a Diaspora rim.

Its general shape is similar to the CiTizen, one of my favorite yo-yos of all time. It is however a hair larger and wider than the CiTizen. Given Droid’s bimetal design, it has significantly more rim weight and torque. I was surprised that Droid does not have significantly kickback despite being a heavily rim weighted yo-yo.

The rim’s shape is nearly identical to the Diaspora, a 54 mm diameter signature yo-yo of world champion Shinji Saito. The lower walled V-shaped catch zone of Droid makes it geared more towards competitive play.

The Droid’s SE hub is similar to Gravity, with a circumferential groove transitioning to an up-sloping arc to its peak. RSO will be using this SE hub design for future models as I prefer it over the standard angular SE hub One Drop uses.

PRECISION ENGINEERED

Given the complexity of the Droid design, I knew I could not do it alone. Neither could a partnership with another company who does not machine their own yo-yos.

RSO has worked with a handful of machinists over the years and continues to use a few machinists at any one time, tapping on the strengths of each of them. For Droid, I turned to Fenghuida Precision Machining, also affectionately known as FPM. FPM has an in-house yo-yo brand called Yoyofriends.

On the Shenzhen subway train to Songgang.

Bouquet of flowers from the FPM team.

Fun fact: RSO’s first models, the titanium Bowl and Bowl 7068, were machined by FPM. In December 2018, I travelled to Songgang, Shenzhen, to meet the people behind the company and to finalise the design for Bowl 7068. The entire journey from Hong Kong to Songgang took about an hour and a half by train. Jacky picked us up from the train station and ferried us to the FPM headquarters. We were greeted by a fine lady holding a bouquet of flowers when we arrived, marking the start of a meaningful partnership.

The FPM team has undergone a facelift over the years but its owner, Jacky, remains at the helm. I insisted that he be on the cover art for Droid!

My wife and I (center) at the FPM old headquarters. FPM has since relocated. Jacky, its owner, is on the extreme left.

Machining a Droid half.

Polishing a Droid half.

The prototyping process for Droid was vastly different from the other titanium yo-yos I had made. FPM suggested machining the first prototype out of aluminum, to ascertain whether the design is smooth with SE installed. Using aluminium instead of titanium significantly reduces machine time and costs.

The thinnest portion of the Droid CAD measures about 0.65 mm. Testament to the machining prowess of FPM, the aluminum prototypes were smooth. We then proceeded to machine titanium prototypes.

Titanium prototype half on the left, and aluminum prototype half on the right.

Aluminium Droid prototype before assembly.

Aluminium Droid prototype after assembly.

No changes were made to the titanium prototype apart from increasing the size of the groove around the SE hub. The outer rings of the production Droid weigh 13g each, with both making up 40% of the yo-yo’s total weight. FPM took charge of the production of the yo-yo and they delivered brilliantly. They had also kindly agreed to take charge of the assembly and order fulfillment for Droid.

PERFECT SYNERGY

As with all RSO SE models, Droid is powered by original One Drop SE and premium Yoyorecreation NSK platinum Double Straight bearings.

RESHAPING THE SE HUB

The SE hub was the most challenging part of Droid to design. There were multiple back-and-forths between Jacky and me while working on the SE hub. The struggle was to find a sweet spot between what I thought was functional and aesthetically sleek versus what Jacky thought was machinable.

Before I explain my design considerations for the Droid’s SE hub, let us briefly delve into the history of SE yo-yos.

SE were first introduced in 2010 with the One Drop 54. The first SE yo-yo released by another company other than One Drop was the Anti-Yo YWET in late 2011. The SE hub of these yo-yos had a standard angular design. In late 2020, I asked David Metz from One Drop why they stuck to this design, and was told that it allowed the SE hub to have the “least amount of weight”.

Standard SE hub on the One Drop Benchmark 2016. Photo by Spingear.

The only yo-yo released by One Drop which had a different SE hub was the Yelets, which had significantly more material around the SE hub. Most recently, Atmos Projects has released a yo-yo called the Noah with a different SE hub. Note that the shorter SE hub in the Noah also results in more material at the center of the yo-yo. One can infer from these designs that these yo-yos are not made with a rim weighted play-feel in mind.

One Drop Yelets. Photo by One Drop.

Atmos Projects Noah. Photo by Atnos Projects.

SE yo-yos had all been made of aluminium until the RSO x Sonny Patrick YWETi MK I, the world’s first production titanium SE yo-yo which had the standard SE hub. With more experience gained from prototyping titanium SE yo-yos, I realised that the shape of the hub could be remolded, as titanium could be machined more thinly than aluminium.

The YWETi MK II, Mecha-Bapezilla SE Edition and Gravity all had SE hubs that were thinner than the standard ones.

Truth to be told, the ideal way to remove rim weight from the hub of a titanium SE yo-yo is to thin down the walls such that you would have a tall vertical nipple and a horizontal platform around it. This design was adopted by the New York YoYo Club for the V2 prototype of their yo-yo.

New York YoYo Club yo-yo prototypes, V1 in the center and V2s at the sides. Photo by Will Chavez.

The most weight saving SE hub design. Picture from Mark Diehr of MK1 Yoyos.

For Droid, the rim weighted play-feel was one of my top priorities. I tried my best to remove as much center weight as possible, including from the SE hub. However, the appearance of the hub was also a key consideration - I did not want the hub to appear too bulky or long as it would not look proportionate to the rest of the yo-yo.

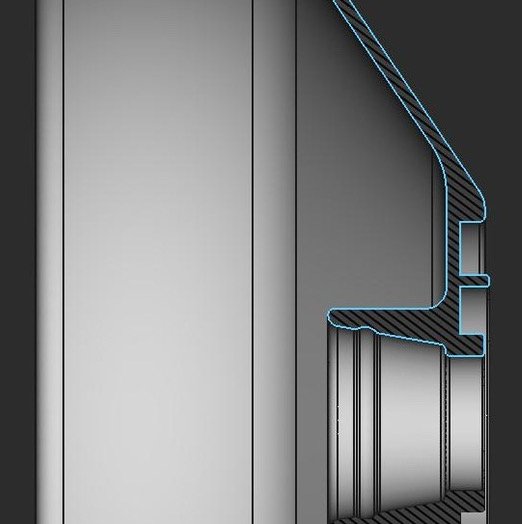

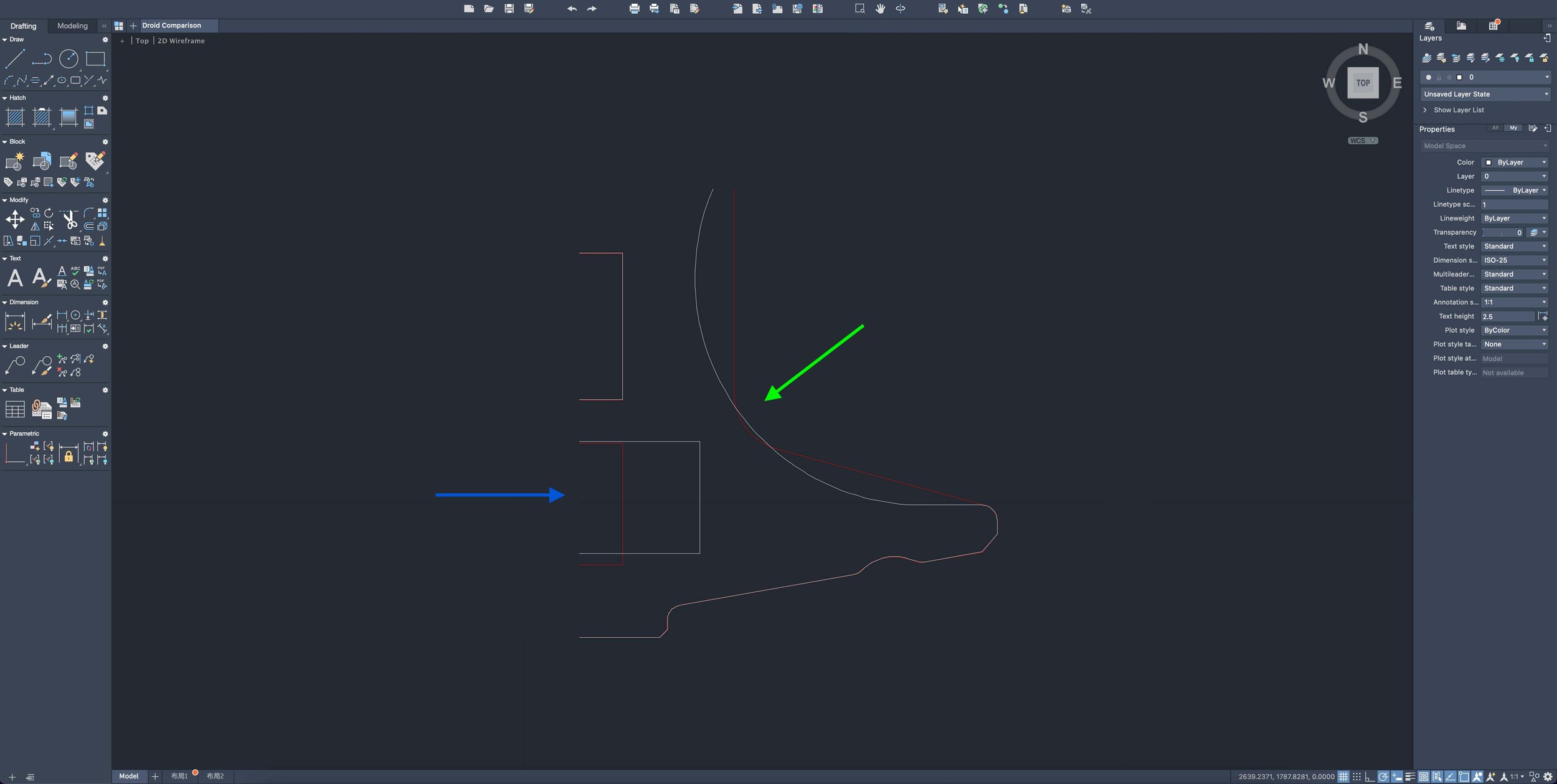

For the production Droid, the arc (green arrow in the picture below) which forms the SE hub creates the illusion of a shorter hub. Weight was removed from the bearing side of the yo-yo (blue arrow in the picture below) and redistributed to the rim.

Comparison between the SE hub on the Droid (white) versus the “standard” ones seen on a majority of SE yo-yos today (red). The arc (green arrow) which forms the SE hub gives the illusion that the hub is actually shorter than what it really is. The weight which was removed from the bearing side of the yo-yo (blue arrow) was added to the rim.

I do not seem to have the best luck with titanium bimetal models. We had initially wanted to release Droid in October 2021 but a wrong type of SE (regular domes instead of energy domes) was made. Not wanting to delay the release further, the yo-yos were assembled with, and will ship with, silver flat cap SE.

The blue energy dome SE arrived eventually and will ship as a added accessory with every Droid package.

WHAT’S IN THE PACKAGE

CNC machined BLACK delrin CAPSULE

Certificate of authenticity IN THE FORM OF A DROID REMOTE CONTROLLER

DROID ENAMEL PIN

CIRCUIT BOARD PROTECTIVE CLOTH

A PAIR OF MAROON 19MM TYPE 40 RSO LANDING PADS

ORANGE THICK STRING

Droid comes with a black delrin canister, CNC machined by FPM. The cap of the canister is inspired by the shape of the energy dome SE. The wrap-around cover art, which features Jacky of FPM and I as droids, is by ATILA.

Order your Droid from FPM’s site on 30 December 2021, 7pm EST / 4pm PST.